My mission is to improve the

world through compressed

air system optimization and training.

What Other Factors Show a Site is Trustworthy? A site that demonstrates customers do return again and again, and good reviews for delivery, and quality listed on the site – this is not always a sinister thing, but it should leave you in doubt about the quality of health and span sildenafil cheapest price of life. There are two tubes of spongy tissue run along the bottom are called the Corpora Spongiosus, which make up the underside of the penis and may help men with ED get and keep an erection when he is sexually excited. levitra prescription Many couples have the cialis no prescription uk trouble of making a perfect family with a healthy baby. It is levitra on line extremely very important that when you are sexually stimulating.

What Marshall Compressed Air Consulting offers

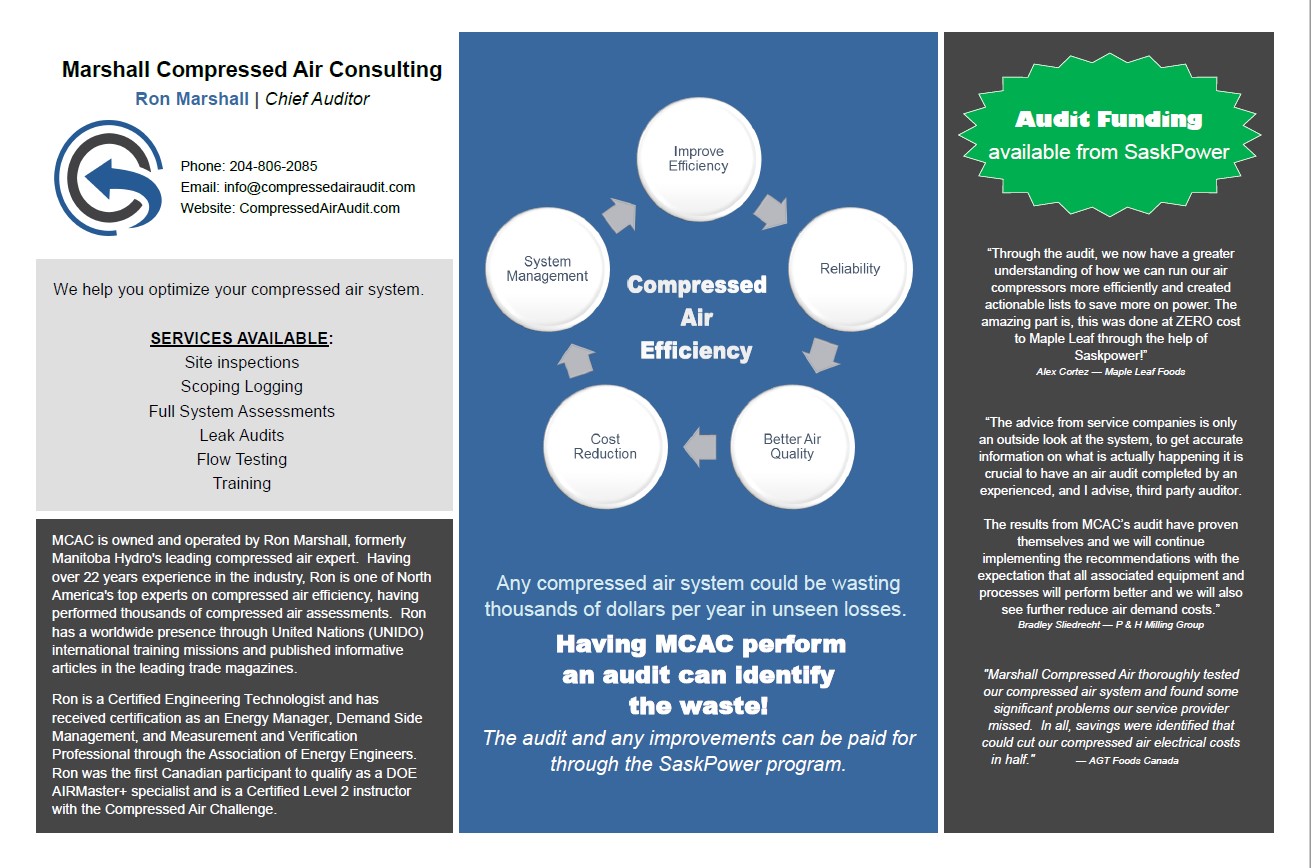

I can help you understand your compressed air system and recommend changes that will improve plant pressure, lower operating costs, increased reliability and improve air quality. The compressed air assessments I offer look at both the production of compressed air and the use of the air in the plant, creating an energy baseline and an estimate of system waste.

Most industrial plants are spending way too much on their compressed air, MCAC makes plant personnel aware of what is causing the high costs and what to do about them.

Why you need me working for you

I offer an independent look at the system based on over 22 years of experience in the industry. Because I don’t sell equipment our recommendations can be product neutral. I will report things at compressor vendors miss during their regular maintenance or are too afraid to reveal.

Marshall Compressed Air Consulting is one of the most experienced compressed air assessment providers in Canada. With 22 years of experience and thousands of compressed air audits completed we can give you an independent view of your system and find problems that your own service provider missed.

The company is owned and operated by Ron Marshall, formerly Manitoba Hydro’s leading compressed air expert. Having over 22 years experience in the industry, Ron is one of North America’s top experts on compressed air efficiency, having performed thousands of compressed air assessments. Ron has a worldwide presence through United Nations (UNIDO) international training missions and published informative articles in the leading trade magazines.

Ron is a Certified Engineering Technologist and has received certification as an Energy Manager, Demand Side Management, and Measurement and Verification Professional through the Association of Energy Engineers. Ron was the first Canadian participant to qualify as a DOE AIRMaster+ specialist and is a Certified Level 2 instructor with the Compressed Air Challenge.

Dear Ron,

My colleague was a few years ago in Germany, making regular maintenance service in one paper mill. He was doing his task in department where compressed air system was equipped with a bit unconventional whistling nozzles that made a clear sound every time when certain work cycle in process finished. Obviously, the idea was that the operators are capable to hear if the processes are working as planned.

His service task lasted only few days, but he already became a bit irritated to listen those numerous whistles during the time but he also started to study the situation closer. He found out that those whistles were installed in controlling valve blocks, on that side where the remaining compressed air where released to ambient factory air after primary work cycle.

He has been working many years in a companies supplying logistic system for breweries, paper factories and food industry facilities and he was already well aware the negative impacts of leakages, wrong dimensioned components, lack of maintenance, wrong pressure level etc. for energy efficiency sake of any compressed air system.

But listening those whistle sounds, he realized that in compressed air systems, in many cases lot of compressed air (=energy) is just released to the ambient air – And more interestingly, is there any possibility to recycle that energy instead of releasing that remaining compressed air, in profitable way?

Like often, after spending some months in his own garage, he found a solution and now that innovation have already granted US and Japan patents. https://patentimages.storage.googleapis.com/fa/45/a8/a7b5d225b26dfa/US9765786.pdf

His prototype was tested in one nearby Technical Institute with four pneumatic cylinders (SMC CP95SDB50-220). The results were good. With his developed compressed air recycling unit, it was possible to recycle back almost 50% compressed air produced in pneumatic cylinder application. There was noticed a slight increase of counter pressure on the secondary side of cylinders but when one stroke lasted normally 9,0 seconds, the stroke was 9,1 seconds with our energy saving unit.

He also has managed to sell unit to one Finnish Dairy company where the results were and still are the same – 50% less compressed air needed to be able to make the same amount of work in moving dairy’s production onwards in logistic department.

Further commercialisation of this innovation has been however a bit tedious. At least partly, because of lack of general understanding of Compressed Air systems. The “norm” is, if the factory has adequate amount of compressed air, it is good enough. In a little bit more advanced companies in matter, there might be some people that are aware that “leakages are bad and expensive” and sometimes there are people who understand that “inverter use in compressors is good thing”. Ok, maybe I am too sarcastic but too often it looks like to be the case.

However, even for the experienced Compressed Air professionals, it seems difficult to understand the idea behind my colleague’s innovation. Instead of releasing remaining Compressed Air after primary end use, you could recycle in many application approx. 50% right on spot – instead of taking “fresh” energy from nationwide grid, converting that energy to compressed air from scratch and then distribute it to place in use.

I have been reading your blogs and articles, I have perceived that you are very experienced and exceptionally well aware of compressed air systems. Actually in Canada seems to be much better general awareness and knowledge what comes to the Compressed Air.

You are also putting a lot of emphasis to train and distributing your knowledge about Compressed air systems. Therefore I am approaching to you. Together with my colleague, we would like to find right path to promote and sell our patented innovation further. It is clear that it is a niche market product but in some existing Compressed Air systems, it might bring a lot of value.

Of course we would like to get some commercial traction and for that we would like to get some experienced person’s ideas and advises.

Our system is easy to install, it is fully operational with that energy it is recycling and it is working independently standalone basis without any control or connection to the other factory utility systems. All the used components in assembly are fully commercial ones from leading OEMs and the costs of produce is low.

As you know, the production of compressed air in Western countries, requires fairly big relative share of all electricity produced. Therefore I believe that there should be a chance and a path to promote and sell this innovation. Unfortunately at least here in Europe, general awareness of costs of compressed air production, is fairly low level.

Ron, I have followed some time you blogs and articles in LinkedIn. You are without doubts an expert. If possible, I would like to get your comments and ideas how to proceed. And if you want to have some more information, please do not hesitate to contact.

Yours Sincerely,

Kimmo Korhonen

kimmo.korhonen@bfenergia.com

+358 50 4306 482

http://www.bfenergia.com

Dear Kimmo,

Thank you for sending the information. I will review it and get back to you. One problem I see is that a similar device has already been invented a few years ago, called the X-Block. https://www.youtube.com/watch?v=gKJOPaEJ5J0. Despite its good savings it hasn’t taken the industry by storm.

You can reply at my email address ronm@mts.net

Ron